PRODUCT INFORMATION

Jadrak Premium Epoxy Finish is an epoxy product exclusively for road wrapping. It has good elasticity and does not cause yellowing. This product is specialized for road building, such as road wrapping and marbling, and is easy to use with a 1:1 ratio of hardener. This is a cap tube container that is convenient to use.

Model name: TW80Capacity: Small capacity - 80ml (main material: 40ml / hardener: 40ml)Mixing ratio: 1 to 1Work time: 30 minutes (working time)Surface hardening time: after 3 hoursLoad availability time: after 48 hours

How to use the product

This technical information is based on operation at normal temperature (around 18 degrees Celsius).

Mixing ratio: 1 to 1

Please use an exact 1:1 ratio of base material and hardener. If the mixing is not correct, it may not harden or may harden too quickly.Available time after mixing: Approximately 30 minutes

If thoroughly mixed, the mixed finish can be used for approximately 30 minutes. It may vary to some extent depending on the amount of hardener, but in general this is the case. Please adjust the amount considering the working time of about 30 minutes.Minimum dryer rotation time: 2~4 hours

After the finish painting work is completed, if you place the rod in the dryer and run it, the finish generally does not drip after 2 to 4 hours, depending on the environment and the amount of hardener. However, except in unavoidable cases, please rotate the dryer on a 24-hour basis.Surface hardening time: After 4 hours

When dried using a dryer at room temperature, the surface usually becomes hard after 4 hours. However, this does not mean that touching it with your finger will not leave a trace. When drying the rod, reapply if you do not like it and do not touch it intentionally.Recoating time available: within 24 hours

If you do not like the paint during the drying process or if the paint is not normal due to an accident, repaint within 24 hours when it is completely hardened. If possible, recoating as soon as possible is essential to ensure a clean application. After full curing, the finish must be removed and rewrapped and painted.Load availability time: after 48 hours

Due to the nature of epoxy, even if the surface is completely cured, there may be parts inside that have not yet hardened. We recommend that you use the completed rod 48 hours after applying the finishing agent.

Please use an exact 1:1 ratio of base material and hardener. If the mixing is not correct, it may not harden or may harden too quickly.Available time after mixing: Approximately 30 minutes

If thoroughly mixed, the mixed finish can be used for approximately 30 minutes. It may vary to some extent depending on the amount of hardener, but in general this is the case. Please adjust the amount considering the working time of about 30 minutes.Minimum dryer rotation time: 2~4 hours

After the finish painting work is completed, if you place the rod in the dryer and run it, the finish generally does not drip after 2 to 4 hours, depending on the environment and the amount of hardener. However, except in unavoidable cases, please rotate the dryer on a 24-hour basis.Surface hardening time: After 4 hours

When dried using a dryer at room temperature, the surface usually becomes hard after 4 hours. However, this does not mean that touching it with your finger will not leave a trace. When drying the rod, reapply if you do not like it and do not touch it intentionally.Recoating time available: within 24 hours

If you do not like the paint during the drying process or if the paint is not normal due to an accident, repaint within 24 hours when it is completely hardened. If possible, recoating as soon as possible is essential to ensure a clean application. After full curing, the finish must be removed and rewrapped and painted.Load availability time: after 48 hours

Due to the nature of epoxy, even if the surface is completely cured, there may be parts inside that have not yet hardened. We recommend that you use the completed rod 48 hours after applying the finishing agent.

Product Features

This product is a high build product.

Depending on the thickness of the coating film that goes up at once, it is divided into high builder and regular. Cases where the paint film is raised high with a single brush stroke are classified as high builder products, and cases where the paint film is raised with multiple brush strokes are classified as regular products. (US standards)Less bubbles are created.

The most annoying and frustrating thing during work is the air bubble problem. If mixing is done properly, you can see many small bubbles. Relatively less air bubbles are generated compared to other products, and they can be easily removed.

Tip: The bubble problem is related to temperature. After applying with a heat gun or hair dryer, increase the heat to some extent. You will see the air bubbles disappear. However, the finishing agent may run off due to excessive heat, so adjustment based on experience is necessary.No yellowing phenomenon.

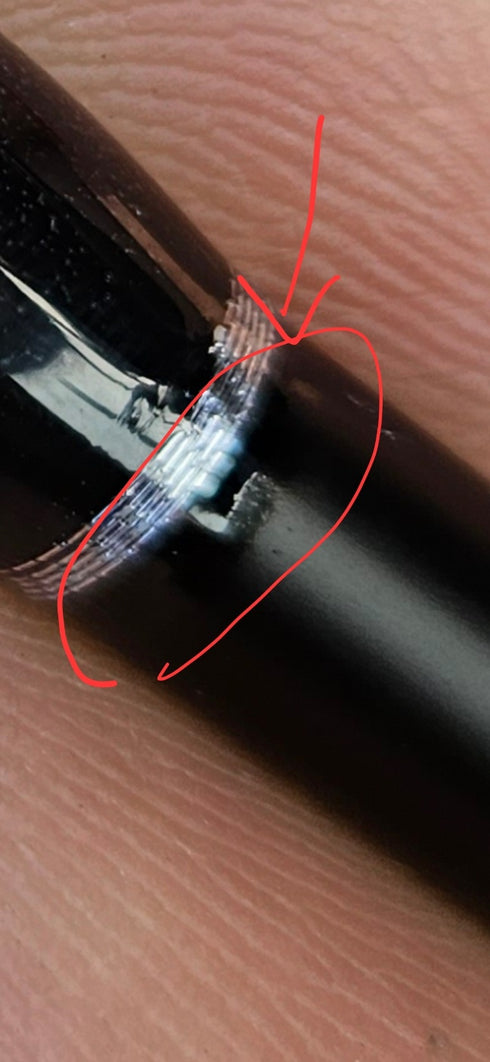

Unlike general epoxy products, it is characterized by no yellowing phenomenon. When mixed and applied, the slight yellowish tint is a critical factor that reduces the completeness of the work. There is also no yellowing phenomenon caused by ultraviolet rays. As time passes and more time is spent in the field, you can also see a light yellow glow. After at least 6 months of testing, no such phenomenon occurred.The elastic film rises.

This is the biggest reason why regular epoxy products cannot be used as a finishing agent. The rod tends to bend, and cracks appear in places where the wrapping finish was applied accordingly. The reason why expensive epoxy finishes are used is to prevent these cracks. This product is a finishing agent that holds the guide firmly yet is soft and elastic. As a chemical powerhouse, Korea's epoxy finishes clearly surpass the performance of historic American products.This is my first time, how should I use it?

It is the same as regular epoxy usage. Mix in an exact 1:1 ratio and mix with a stick for at least 2-3 minutes. What is easy to overlook is that accurate application is difficult without sufficient mixing. Then, apply it once with a brush or other material, then repeat the process of applying it again after some time to raise the paint film to the desired height. Next, of course, you can put it in the dryer and dry it.

Depending on the thickness of the coating film that goes up at once, it is divided into high builder and regular. Cases where the paint film is raised high with a single brush stroke are classified as high builder products, and cases where the paint film is raised with multiple brush strokes are classified as regular products. (US standards)Less bubbles are created.

The most annoying and frustrating thing during work is the air bubble problem. If mixing is done properly, you can see many small bubbles. Relatively less air bubbles are generated compared to other products, and they can be easily removed.

Tip: The bubble problem is related to temperature. After applying with a heat gun or hair dryer, increase the heat to some extent. You will see the air bubbles disappear. However, the finishing agent may run off due to excessive heat, so adjustment based on experience is necessary.No yellowing phenomenon.

Unlike general epoxy products, it is characterized by no yellowing phenomenon. When mixed and applied, the slight yellowish tint is a critical factor that reduces the completeness of the work. There is also no yellowing phenomenon caused by ultraviolet rays. As time passes and more time is spent in the field, you can also see a light yellow glow. After at least 6 months of testing, no such phenomenon occurred.The elastic film rises.

This is the biggest reason why regular epoxy products cannot be used as a finishing agent. The rod tends to bend, and cracks appear in places where the wrapping finish was applied accordingly. The reason why expensive epoxy finishes are used is to prevent these cracks. This product is a finishing agent that holds the guide firmly yet is soft and elastic. As a chemical powerhouse, Korea's epoxy finishes clearly surpass the performance of historic American products.This is my first time, how should I use it?

It is the same as regular epoxy usage. Mix in an exact 1:1 ratio and mix with a stick for at least 2-3 minutes. What is easy to overlook is that accurate application is difficult without sufficient mixing. Then, apply it once with a brush or other material, then repeat the process of applying it again after some time to raise the paint film to the desired height. Next, of course, you can put it in the dryer and dry it.

CUSTOMER REVIEWS